This machine is specially designed for closure box and frame box, and it is a product carefully developed by our company. It has a one machine adjustment function. You only need to input the size of the hard cover and the box to complete the machine adjustment. The machine adjustment only takes 5-10 minutes.

Switching to previously made boxes can be done in just 2 minutes with a one-key switch. No machine leader is needed, avoiding situation where no one can adjust the machine after the staff leaves; it can handle orders of any size, avoiding the situation where only large orders are processed on the, thus improving the utilization rate of the equipment.

| MAIN CONFIGURATION | |

| Servo Motor | inovance |

| Servo Driver | |

| PLC | |

| Photosensor | |

| Vacuum Switch | |

| Power Switch | MeanWell |

| Proximity Switch | Schneider Electric SA |

| Linear Module | AMT |

| Hot Melt Glue Manchine | JING TAI |

| Pneumatic Element | AIRTAC |

| MAIN TECHNICAL PARAMETER | |

| Model | YY-900E |

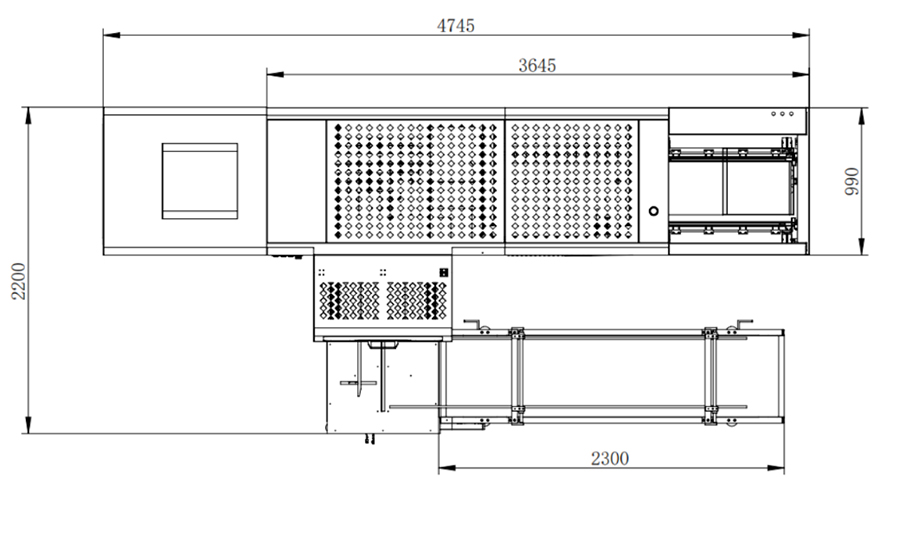

| Dimension | 4745*2200*2000mm |

| Machine weight | Around1000KG |

| Speed | 22-30PCS/min |

| Max case size | 900*450mm |

| Max case size | 90*95mm |

| Max box height size | 130*130mm |

| Max Inner box height size | 450*450*150mm |

| Precision positioning | ±0.1mm |

| Power supply | AC220V |

| Power | 8KW |

| Air pressure | 0.6Mpa |

MAIN SPECIFICATION

PROCESS FLOW

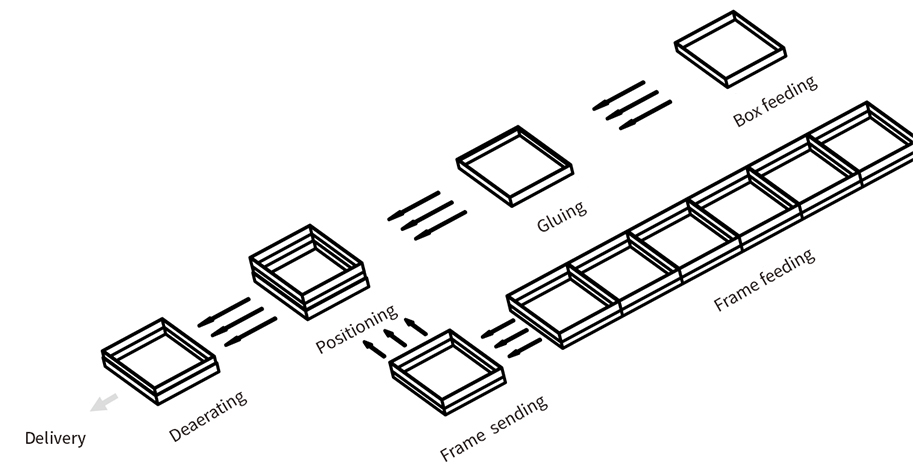

① BOOK BOX MODE

PROCESS FLOW

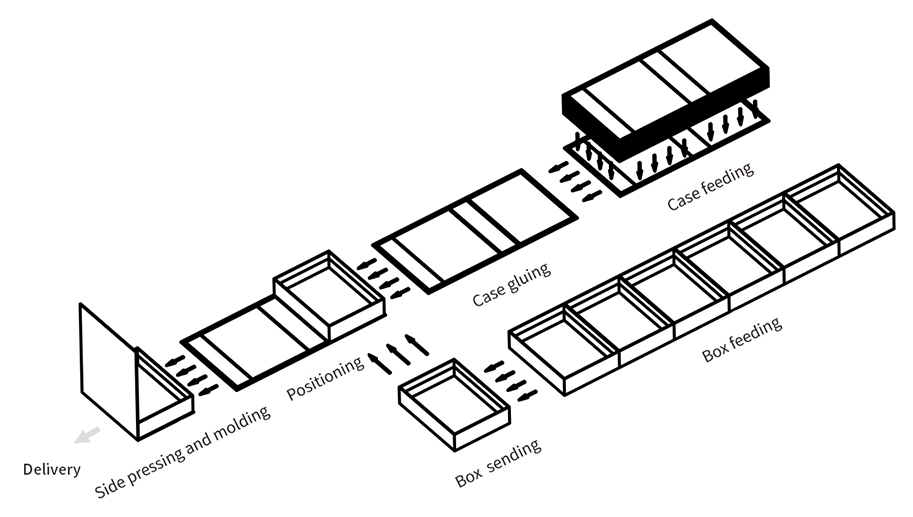

②FRAME BOX MODE