| MAIN CONFIGURATION | |

| Servo Motor | Panasonic/xinjie |

| Servo Driver | |

| PLC | |

| Photosensor | |

| Vacuum Switch | |

| Power Switch | MeanWell |

| Proximity Switch | Schneider Electric SA |

| Linear Module | AMT |

| Hot Melt Glue Manchine | JING TAI |

| Pneumatic Element | AIRTAC |

| MAIN TECHNICAL PARAMETER | ||

| Model | YY-1000D | YY-1200D |

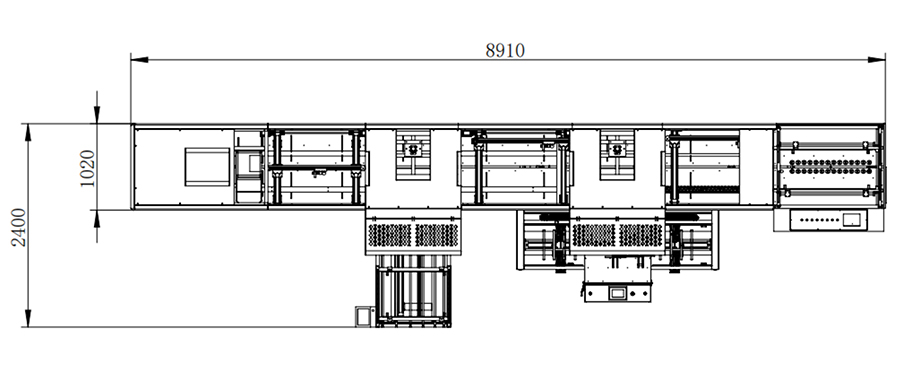

| Dimension | 8910*2400*2000mm | 9710*2400*2000mm |

| Machine weight | Around 1900KG | Around 2500KG |

| Speed | 15-20PCS/min | 10-18PCS/min |

| Max case size | 1000*690mm | 1200*900mm |

| Max case size | 100*200mm | 200*200mm |

| Case Width Size A | 90-450mm | 135-600mm |

Wing length Size (Two side boards) | 100-650mm | 120-890mm |

Wing width Size (Two side boards) | min 30mm | MINI35mm |

| Wing center width size(Two side boards) | min 60mm | MINI65mm |

| Side board combination length (three side boards) | 300-650mm | 300-840mm |

| Precision positioning | ±0.1mm | ±0.1mm |

| Power supply | AC220V | AC220V |

| Power | 6KW | 7KW |

| Air pressure | 0.6Mpa | 0.6Mpa |

MAIN SPECIFICATION

PROCESS FLOW

ADVANTAGES 1.Save labor: 10-13 people 2. Increase production capacity:800-1000PCS/H 3. Improve the accuracy: the box forming size fits the mold 4. Save the cost of double-sided tape: the four triangles can be hot-melted without sticking double-sided tape |  |